Smart home devices, which help automate household systems and promote energy efficiency, are popular applications within the Internet of Things (IoT) space. At the heart of many of these devices is a new generation of infrared (IR) detection sensors.

At the heart of many of these devices is a new generation of infrared (IR) detection sensors. These sensors are essential for the operation of systems such as motion-detecting security cameras and safety lights, and for presence-sensing applications that can promote energy efficiency, such as smart heating, ventilation and air-conditioning (HVAC) systems.

At the heart of many of these devices is a new generation of infrared (IR) detection sensors. These sensors are essential for the operation of systems such as motion-detecting security cameras and safety lights, and for presence-sensing applications that can promote energy efficiency, such as smart heating, ventilation and air-conditioning (HVAC) systems.

When connected by the IoT, the functionality will become even more intelligent and convenient – requiring ever more sensory data from the operating environments – including temperature, motion and human presence.

Challenges of IR-sensor-based application development

Demand is surging, but development expertise in sophisticated IR sensors is limited. Different design approaches each have their own merits.

Development time can be condensed by designing electronics with existing design blocks. Sensors of all kinds need to be digital and capable of dropping in and communicating with the surrounding electronics.

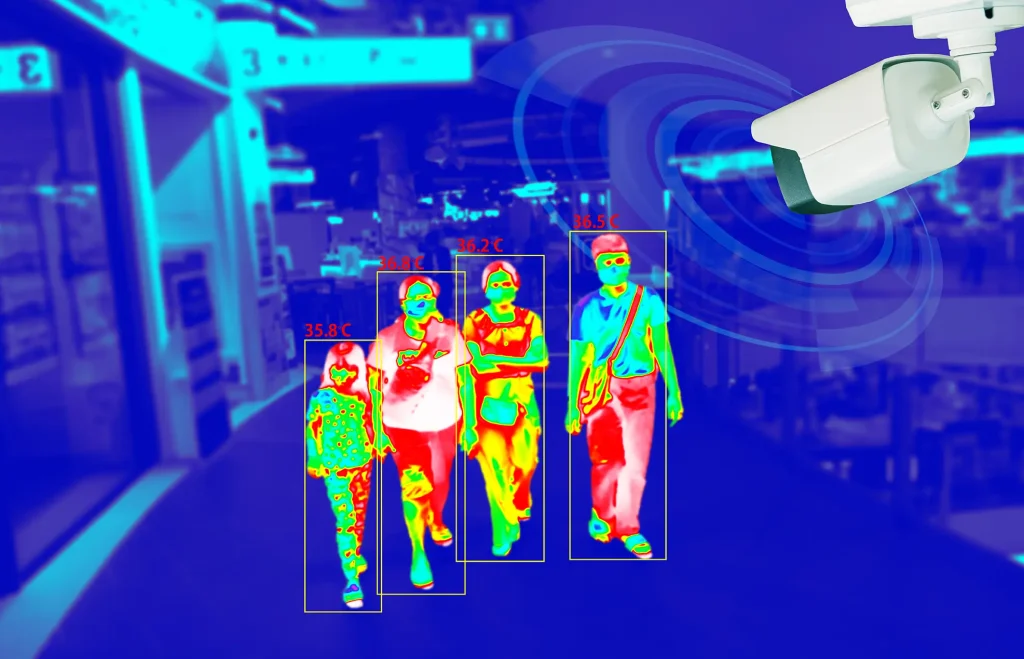

Sensors such as the Excelitas Calipile work well as they offer multiple modes and a digital interface. Calipile is a single point detection device; another approach is to use pyrodetectors to detect movement, using multi-element pyros or deploying multiple devices to increase the detection capability. A further level of information can be captured by moving up into the low resolution end of imaging solutions – for example the 80 x 32 pixel resolution of Mitsubishi’s MelDIR electric diode infrared sensor can provide highly detailed thermal images for accurately distinguishing between humans and other heat sources, and enables the identification of specific human behaviour, such as walking, running or raising hands.

One sensor does not fit all applications, and the ability to customise the sensor and its optical elements can bring significant advantages to the design. OEMs are looking for ways to pack more technology and function into smaller devices, but there are competing drivers in the development. Design engineers need easily integrated sensors to enable shorter product design cycles – but a customised sensor that meets the exact needs of the application will bring down the system cost and size.

System designers often need assistance with the optoelectronic aspects of the sensor to get the most effective solution – optoelectronic devices are a niche design skill and their integration and assembly can be challenging. There is a limited number of companies with the right skills and experience to tackle such demanding requirements, but finding the right development partner opens up significant benefits.

Real world experience with a range of sensor sub-systems is vital for adding real value to these IoT projects. Practical advice on product and manufacturing enhancements drive better yields, higher performance and increased reliability, as well as lower project costs in many cases.

Expertise in production engineering and Design for Manufacture (DFM) enables the smooth transfer of products from research and development prototypes into real life production. Experience with approvals and qualifications is vital. Working to standards and processes such as ISO 9001-2000, QS9000, ISO/TS16949 and ISO 13485, as well as AS9120, is vital to ensure a smooth manufacturing flow and reliable end product with a customised sensor.

New trends and features for IR sensor applications

Advances in proprietary sensor substrate designs are yielding greater sensor area, which translates to improved sensitivity (such as quicker triggering from weaker event signals) and extended effective sensing range. At the same time, the latest SMD sensor designs are fully capable of effective event detection at ranges up to 10 feet without needing bulky magnifying lenses or windows. This can dramatically simplify a sensor sub-system design.

Signal processing is also a key part of the sensor sub-system. Software controlled functions provide designers with flexibility, while the latest controllers allow the sensors to monitor and detect multiple factors and distinguish between motion- detection events and presence monitoring.

This can streamline the ability to employ various sensor points in a host system mesh network and communicate specific data from various points to the host system’s central control.

The power consumption of the sub-system is also a key consideration. Optimising the sensor’s power requirement not only prolongs the life of remote and mobile smart devices, but will reduce the device footprint by significantly minimising power requirements. Battery powered devices are likely to require sensors that operate at 1.8 V and need less current.

Working with a knowledgeable, specialist team such as Solsta is key to customising the sensor and digital signal processing for IoT designs. Our expertise in aligning optical components such as lenses with the sensor and then combining these with the necessary digital compensation and filtering functions is a rare combination. Adding in the ability to optimise the design for high-volume surface-mount manufacturing with high yields adds yet another layer of complexity to the design of such system.

If this can be achieved, then the benefits cascade throughout the design process. Using customised sensor sub-systems enables smaller, more power efficient equipment to be developed as part of the Internet of Things. This brings huge benefits to the end customer in usability, lower running costs and longer equipment lifetime.